Building stairs can be a challenging but rewarding project. Whether you're looking to add functionality and safety to your home or simply want to enhance its aesthetic appeal, constructing stairs is a skill worth mastering. In this DIY guide, we will explore the step-by-step process of building both mill-made and carpenter-built stairs. So, grab your tools and let's get started!

Understanding the Different Types of Stairs

There are two main classes of stairs: mill-made and carpenter-built. Mill-made stairs are pre-fabricated in a mill shop and delivered to your job site as a kit. They are ready for assembly and installation. On the other hand, carpenter-built stairs are constructed on-site by a carpenter. This type of fabrication is less expensive and allows for the stairs to be covered with carpet.

Carpenter-built stairs can be customized with a hardwood or paint-grade skirt board, and a simple wall-mounted railing can be added to either type of stair for a finishing touch.

When building stairs, functionality should be your top priority. Ensuring accuracy and safety is crucial. Before starting construction, consult both national and local building code requirements. Different municipalities may have stricter codes, so checking beforehand will save you from any future rebuilding.

Design and Material Considerations

Once you have determined the appropriate building codes for your area, it's time to consider the design aspects of your stairs. The choice of construction materials will greatly impact the final outcome of your project. Quality materials will yield a quality job, even if the stairs will be covered with carpet and not seen by others. Using lower-grade materials with knots and voids may result in cracking down the line. Most lumberyards carry stock specifically designed for stair construction.

Image: Illustration of stair construction

Image: Illustration of stair construction

Layouts and Calculations

Once you have familiarized yourself with the building codes and chosen your materials, it's time to start the layout and calculations of your stair. Begin by sketching a rough blueprint of your staircase on paper.

For the purpose of this example, let's consider a straight stair. The building code we will follow is BOCA 96 for residential use. According to this code, the maximum riser height should be 7 3/4 inches, and the minimum tread run should be 10 inches.

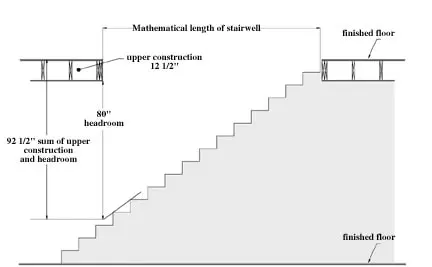

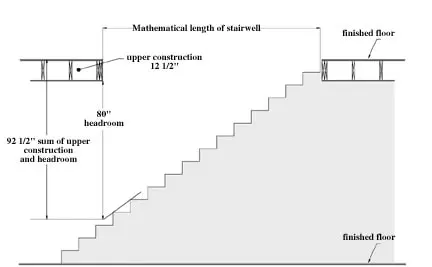

To determine the size of your stairwell, ensure proper headroom for safe passage. Take into account the finished floor-to-floor distance and the necessary headroom. In our example, the nosing will be 1 1/4 inch, the tread run will be 10 inches each, and the headroom will be 6 feet 8 inches.

By dividing the total finish rise by 7.5, you can determine the number of risers needed. Round up to the nearest whole number. Divide the total finish rise by the number of risers to calculate the height of each riser.

Image: Calculations for stair construction

Image: Calculations for stair construction

Knowing the number of risers will also give you the number of treads. In our example, we have 15 treads. Multiply the number of treads by 10 inches (tread depth) and add 1 1/4 inch for the nosing and 3/4 inch for the top riser to determine the total run of the stair.

To calculate the length of the stairwell, account for the required headroom and upper-floor construction. Divide the total thickness by the riser height to determine the number of treads needed in the clear opening. Multiply the number of treads in the clear opening by the tread depth and add the nosing and top riser thickness to determine the stairwell length. Finally, add an extra inch to accommodate the finished width of the stair.

Image: Stairwell plans

Image: Stairwell plans

Cutting the Stair

With your plans in hand, it's time to start cutting. Remember the golden rule of carpentry: measure twice and cut once. Precision is key, as mistakes can be costly and frustrating.

Ensure your work area is clean and well-lit for optimal visibility. Comfortable surroundings make a challenging task a little easier.

How to Build Stair Stringers

Lay out the stringers to start the actual stair construction process. Set the rise and run of the stair on a framing square. Adjust the clamps of the framing square to 7 3/8 inches by 10 inches. Mark off the number of treads and risers required for your stair. Begin with the first riser and end with the top riser, remembering to draw in the second-floor line. Count the number of risers to avoid any layout errors. Repeat this process for all three stringers.

Image: Stair building guide

Image: Stair building guide

After marking the treads and risers, make final adjustments to the stair stringer. Tweaking the design may be necessary to ensure all risers are in code compliance. For example, adjusting the top and bottom risers may be required when adding the thickness of the tread to the bottom cut and deducting it from the top cut.

Once the stringers are laid out correctly, use a power saw to cut off the triangular portions. Be careful not to cut beyond your marked layout lines, as this can weaken the stringers. Finish cutting the triangles with a handsaw. Check that all three stringers match perfectly before proceeding. Three perfect matches are crucial for a successful stair construction project.

Take the left and right stringers and position them on top of the skirt boards. Trace the cut lines where the stringer meets the floor and the top riser. Cut along these lines, making a plumb cut at the bottom of the board to match the height of the baseboard. Attach the skirt boards to the stringers. If no drywall is present, fill out the stringers to match the thickness of the drywall. Securely attach the stringers to the studs or blocking.

Image: Stair construction process

Image: Stair construction process

Stair Inspection and Finishing Touches

Once the stringers are in place, double-check all your cuts for level, plumb, and accurate measurements. Ensure that the top and bottom risers are suitable for the finish tread height. The top riser should have a tread thickness of more than 7 3/8 inches, while the bottom riser should have a tread thickness less than that.

After verifying your cuts, rip the risers to the correct heights and nail them into place. Glue and nail the treads for added durability.

Image: Nail the treads and risers to the stringers.

Image: Nail the treads and risers to the stringers.

Your stair is now complete, except for the wall or handrail. To meet code compliance, install a wall-mounted handrail at a height of 34 inches above the leading edge of the tread. The handrail should be 198 inches in length and include wall rail brackets screwed into studs or backing every 4 feet. For open rail sections, mount balusters on an angle cap.

Congratulations! Your DIY stair construction project is finished. Now it's time to enjoy the fruits of your labor and admire the beautiful staircase you've created.

Building stairs is considered an art form, and it takes practice to master this craft. Don't expect to learn everything from a single article. Many experienced carpenters still face challenges when building stairs. Be patient, follow the guidelines, and with time, you'll become proficient in stair construction.

Stair-Building Tips

Here are a few additional tips to enhance your stair-building skills:

- To create a softer edge where the carpet breaks over the tread, route the edge with a 1/2-inch round overbite before installing the treads into the stringers.

- If your material is splitting, predrill the holes. This can prevent future squeaking.

- Use glue blocks between the tread and riser intersection for added stability.

- Seal the underside of your stairs to prevent squeaking and warping.

Stair-Building Terminology

Here are some common terms you may come across during stair construction:

- Riser: The vertical surface between two treads.

- Carriage Stringer: The support for the treads and risers, usually cut to have treads sitting on the horizontal plane and risers nailed to a vertical cut.

Remember, building stairs requires patience, attention to detail, and a willingness to learn from your mistakes. With practice and persistence, you'll soon find yourself mastering the art of stair construction.