Centrifugal blowers are a vital component in various industrial processes, providing efficient air movement through the unique force generated by the rotation of an impeller. Their versatility, durability, and low maintenance make them a popular choice for industrial and commercial applications. In this article, we will explore the different types of centrifugal blowers and their uses, as well as the benefits they offer.

What is a Centrifugal Blower?

At its core, a centrifugal blower is a motor or pump that pulls air or fluids into the blower and expels them through the outlet, utilizing the centrifugal force generated by the rotation of its impeller. Key components of a centrifugal blower include the impeller, housing, and drive mechanism. The impeller, with its series of blades mounted on a central hub, plays a vital role in the blower's efficiency and ability to move air effectively.

The drive design, whether it's a belt or direct drive, determines the rotation speed of the impeller. This speed, combined with the blower's efficient design, allows for a wide range of applications, including dryers and HVAC systems. The angle of the blades, whether forward curved, backward curved, or radial, further influences the blower's efficiency and effectiveness in moving air.

Caption: Centrifugal Blower

Caption: Centrifugal Blower

Types of Centrifugal Blowers

Centrifugal blowers are commonly referred to as blowers or fans interchangeably. This distinction prevents confusion with axial fans that move air in a direct path. The blade angle is a significant differentiating factor among various types of centrifugal blowers. The three main types are forward curved, backward inclined, and radial.

Forward Curved Centrifugal Blowers

Forward curved centrifugal blowers have blades that curve towards the direction of the impeller's rotation. These blades are shorter compared to other types, allowing for a higher velocity vector and increased pressure. However, they are less efficient overall. These blowers, also known as squirrel cage blowers, are commonly used in domestic furnaces and air conditioning units.

Caption: Squirrel Cage Wheel

Caption: Squirrel Cage Wheel

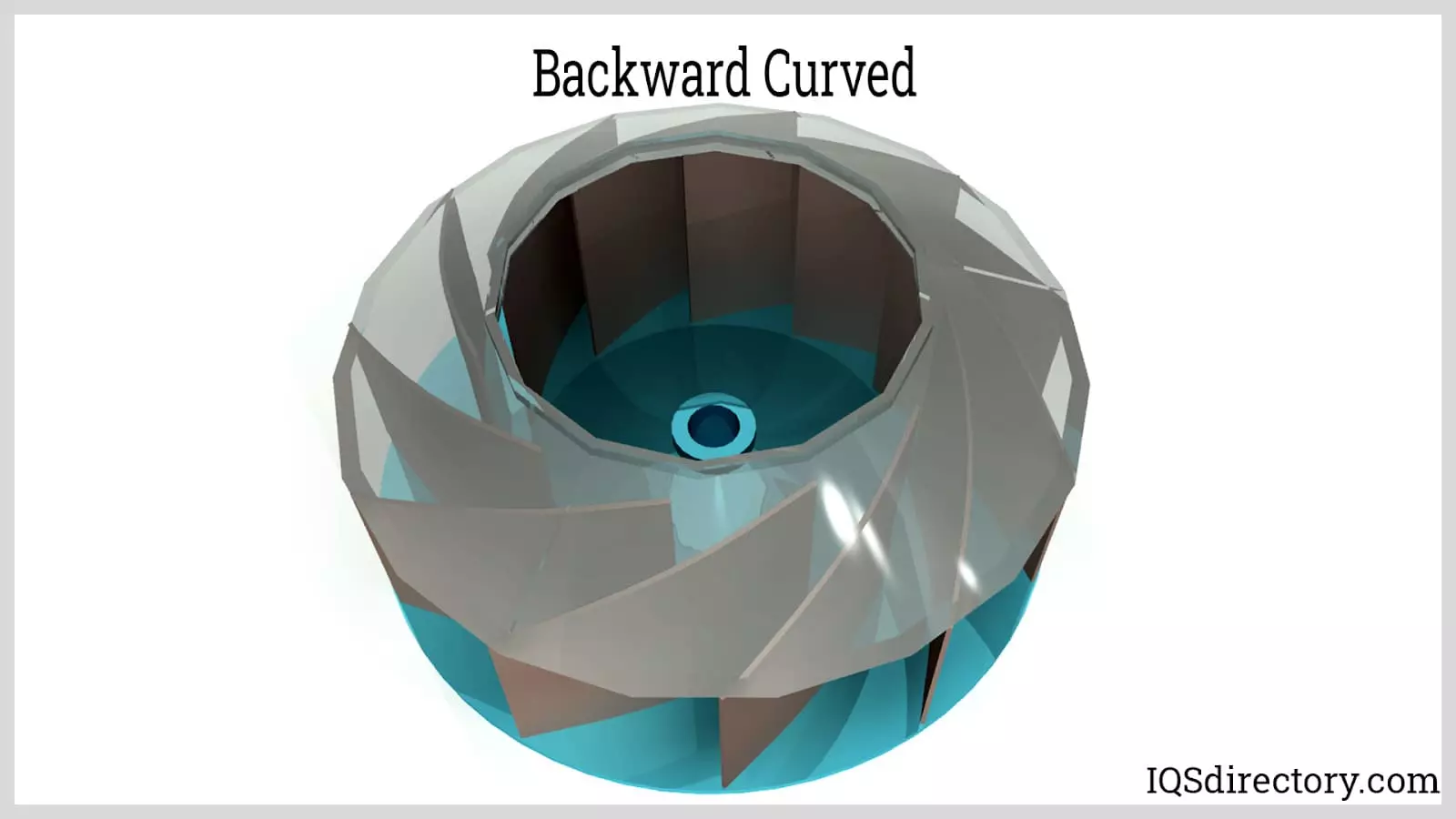

Backward Inclined Centrifugal Blowers

Backward inclined centrifugal blowers feature blades that move in the opposite direction of the impeller's rotation. These blades are larger and heavier, enabling these blowers to operate at high speeds with exceptional efficiency. They are commonly used in high-static applications.

Curved Single Thickness Blade

This blade design is ideal for applications involving small amounts of corrosive material and high temperatures. They often include liners and hard surfaces for added protection.

Caption: Backward Curved

Caption: Backward Curved

Flat Single Thickness Blades

Flat single thickness blades are strong, efficient, and cost-effective alternatives. Although slightly less efficient, easily installed liners compensate for this.

Curved Airfoil

Curved airfoil blades are used in high-volume airflow applications with low pressure. They excel at cleaning air or moving gases with small amounts of erosive material.

Radial Centrifugal Blowers

Radial centrifugal blowers have straight radial blades that prevent dirt and dust from sticking. This design makes them well-suited for harsh conditions and material handling applications. They generate medium to high pressure and move higher volumes of fluids.

Caption: High Pressure Centrifugal Blower Blades

Caption: High Pressure Centrifugal Blower Blades

Airfoil Centrifugal Blowers

Airfoil centrifugal blowers provide high-volume airflow with low power consumption. Their design allows for efficient handling of large volumes of clean air at low to moderate static pressure. They operate at greater speed and efficiency compared to backward inclined blowers.

Caption: Airfoil Centrifugal Blower

Caption: Airfoil Centrifugal Blower

Radial Tip Centrifugal Blowers

Radial tip centrifugal blowers have a compact design and are designed for high-volume airflow with high-pressure requirements. The tipped blades facilitate the movement of clean and dirty airflow, making them ideal for various applications. They are often made of stainless steel with durable linings to resist corrosion.

Caption: Radial Tipped Centrifugal Blower

Caption: Radial Tipped Centrifugal Blower

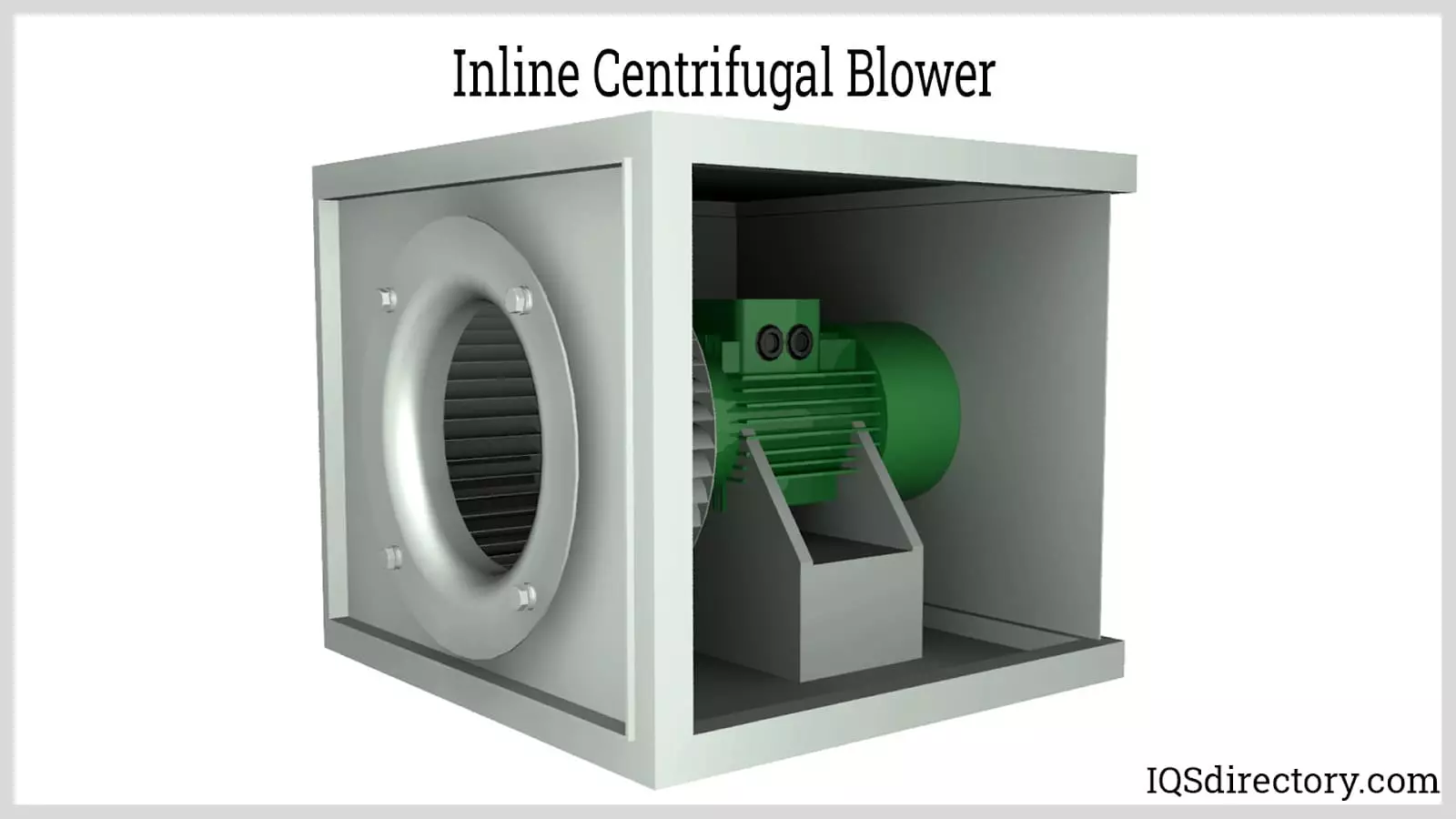

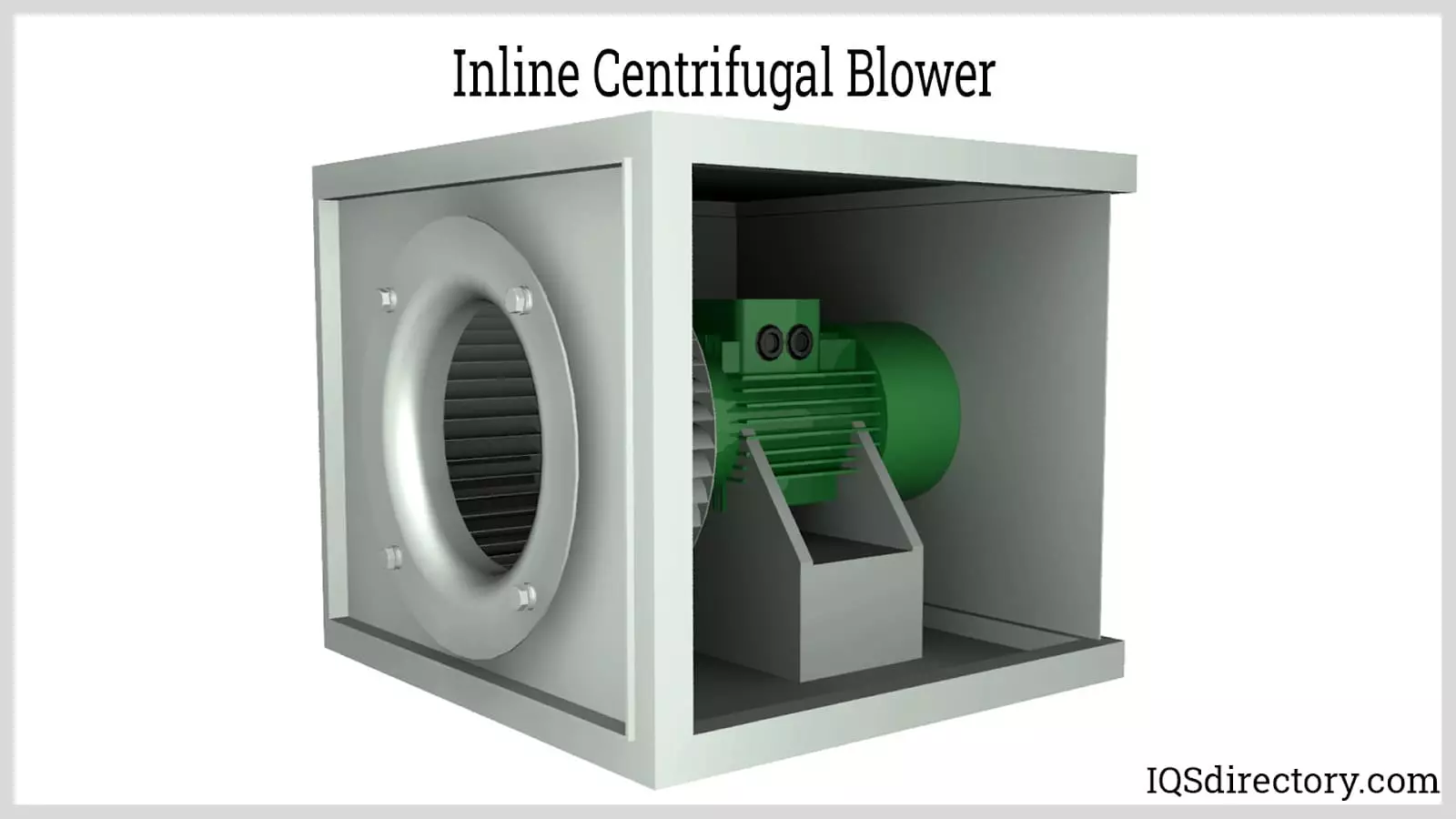

Inline Centrifugal Blowers

Inline centrifugal blowers offer rugged construction and serve as clean air boosters for supply and exhaust systems. They are versatile and can be installed vertically or horizontally at any angle. Their compact design combines the advantages of centrifugal and axial blowers.

Caption: Inline Centrifugal Blower

Caption: Inline Centrifugal Blower

Plug Centrifugal Blowers

Plug blowers, also known as open type fans or blowers, are used in high-temperature applications, such as autoclave vessels or dust collection systems. Each plug blower is engineered to meet specific operating conditions and requirements, ensuring optimal performance.

Caption: High Temperature Plug Blower

Caption: High Temperature Plug Blower

Volute Centrifugal Blower

Volute centrifugal blowers use a spiral-shaped casing to regulate flow and convert kinetic energy into static pressure. The casing's design gradually reduces the flow's velocity, resulting in increased pressure. Volute casings can be single or double volute, with the latter offering two discharge paths.

Caption: Single and Double Volute Casings

Caption: Single and Double Volute Casings

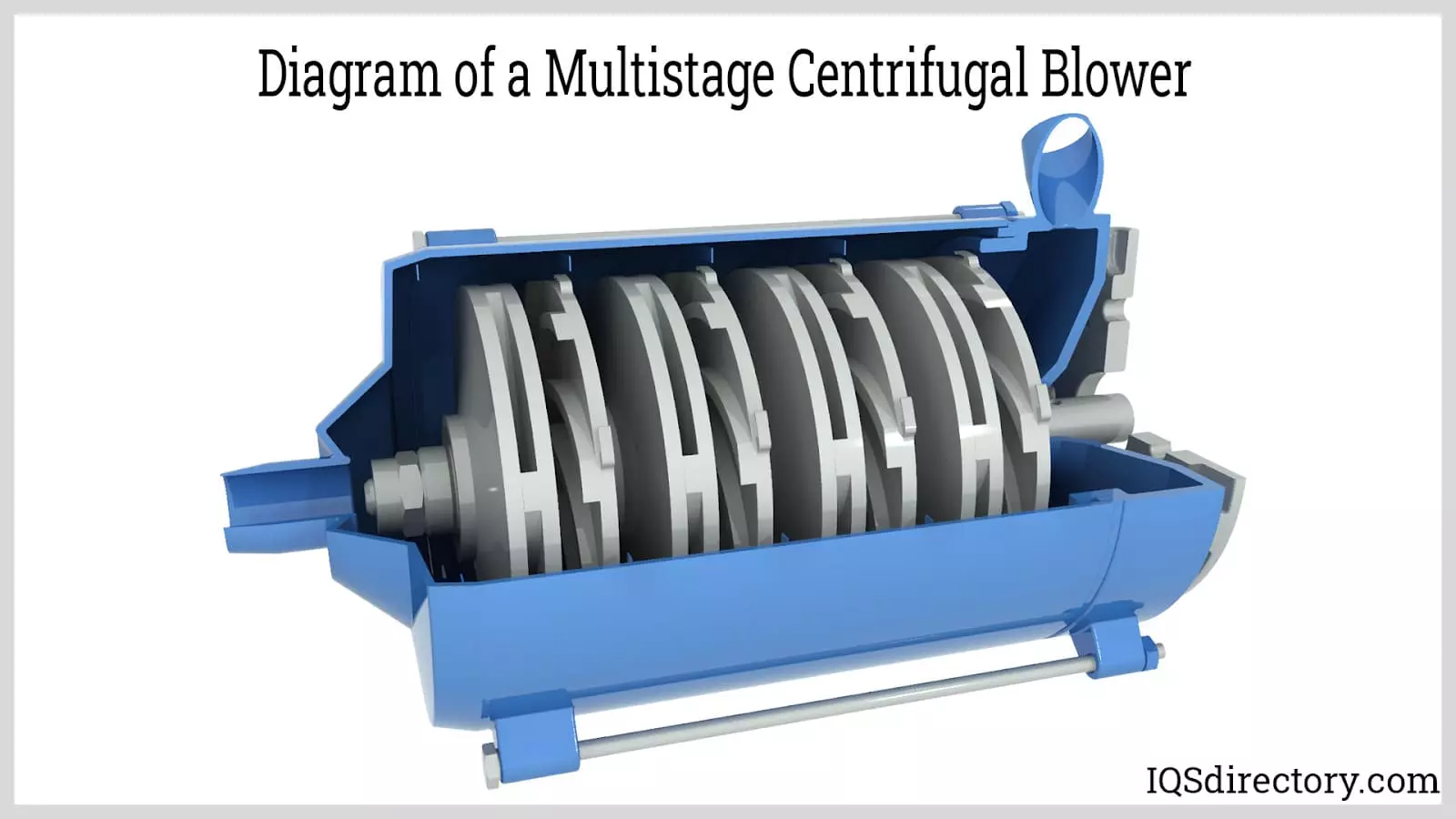

Multistage Centrifugal Blowers

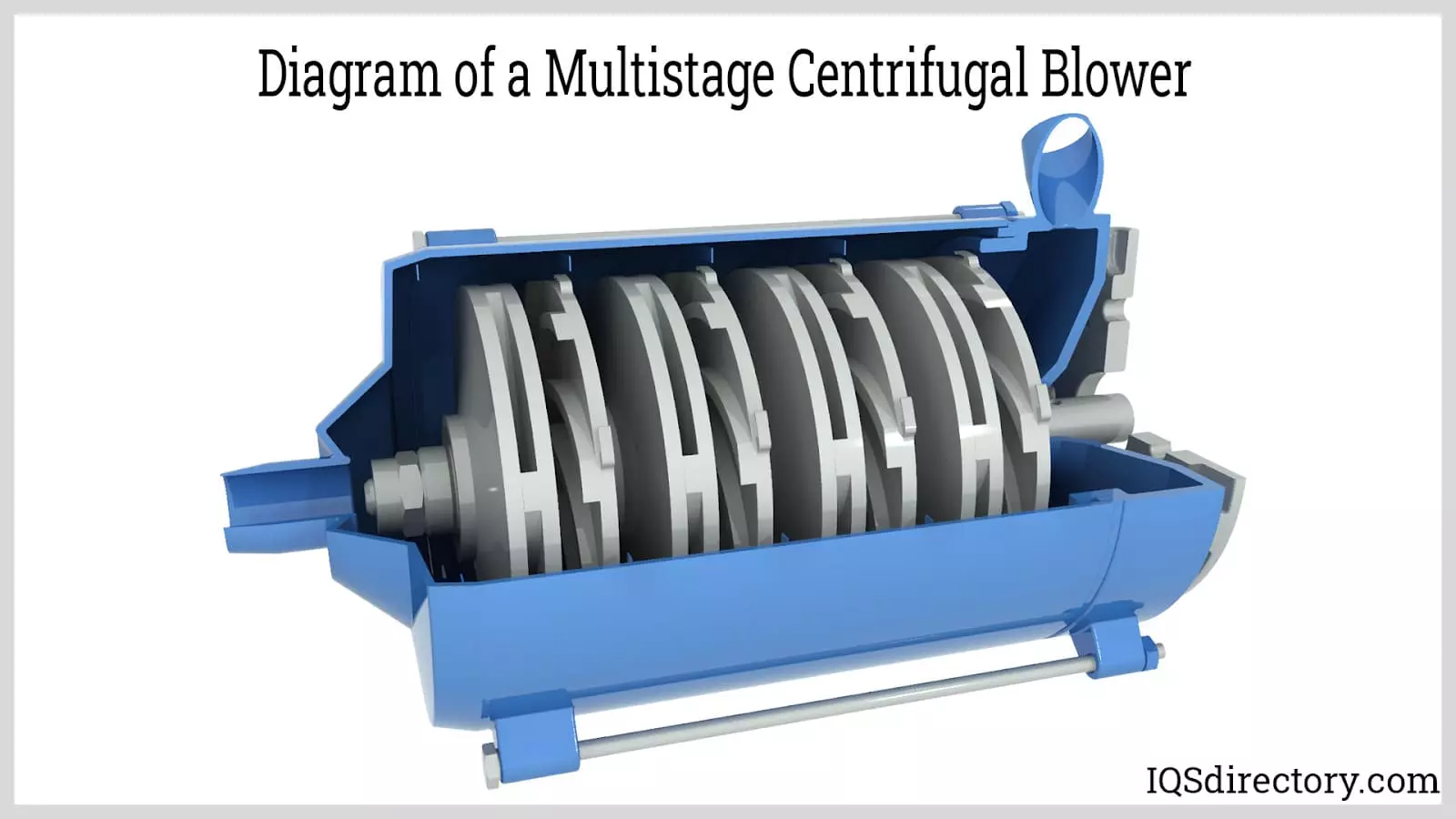

Multistage centrifugal blowers utilize multiple impellers to compress the flow, enabling higher pressure generation with a smaller motor and lower energy consumption. Each stage acts like a single-stage centrifugal blower, compressing the flow as it progresses. The number of stages determines the blower's ability to produce high pressure.

Caption: Diagram of a Multistage Centrifugal Blower

Caption: Diagram of a Multistage Centrifugal Blower

How Centrifugal Blowers Work

Centrifugal blowers are renowned for their efficiency and reliability in industrial air movement. They consist of a motor, a fan wheel (impeller), and a housing. The motor powers the impeller, which pulls in air and expels it at a right angle, creating the necessary airflow. Unlike traditional fans, centrifugal blowers generate pressure by accelerating air tangentially to the impeller's blades.

Electric Motor

The electric motor is the heart of a centrifugal blower. It provides the rotational force required to drive the impeller. Centrifugal blowers can have direct or indirect drive configurations. Direct drive blowers connect the drive shaft directly to the motor, offering greater power but increased torque. On the other hand, indirect or belt-driven blowers utilize a flexible coupling or belt for lower torque and maintenance costs.

Caption: Direct Drive Centrifugal Blower

Caption: Direct Drive Centrifugal Blower

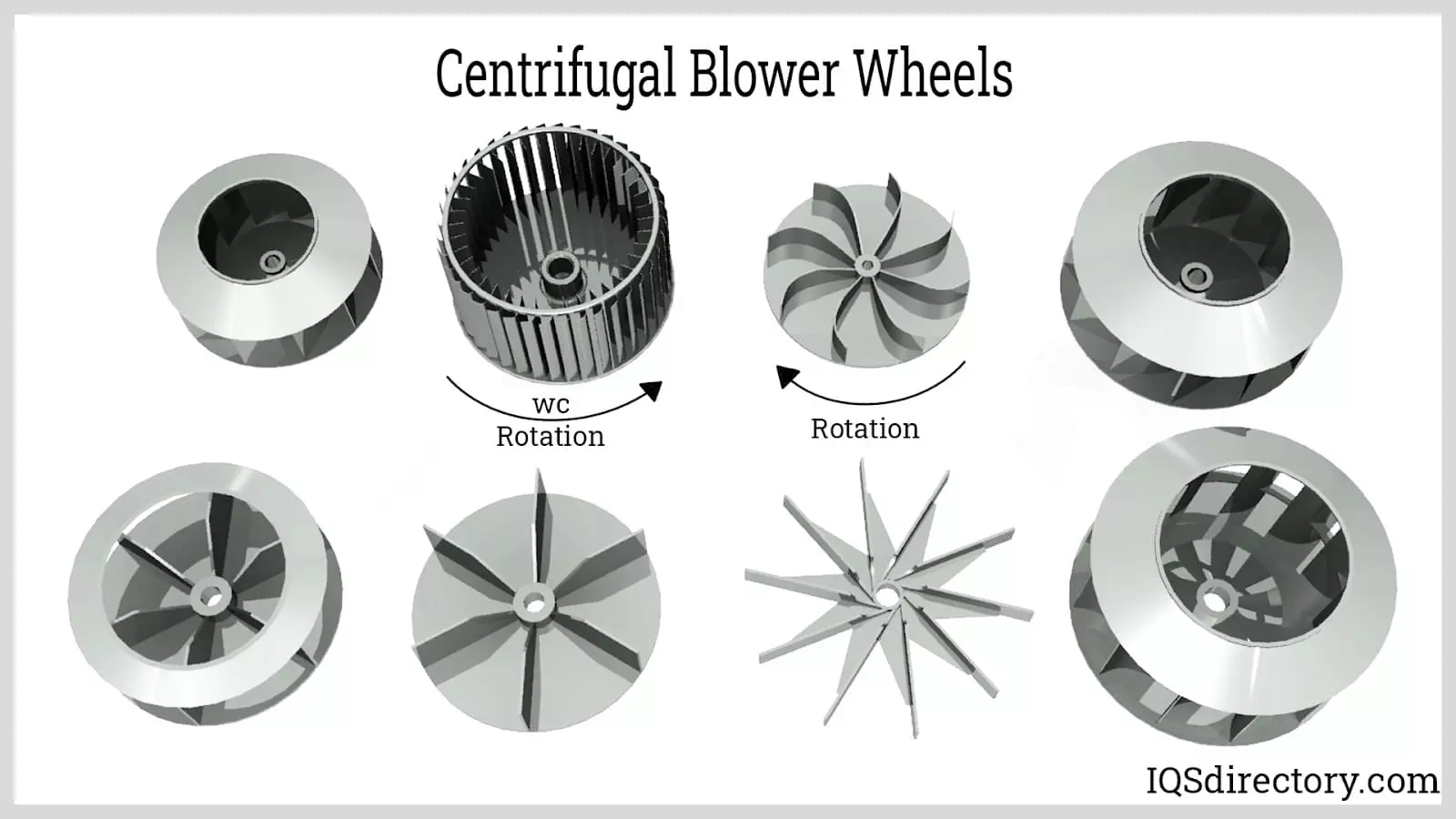

Fan Wheel or Impeller

The fan wheel or impeller, connected to the motor, plays a crucial role in the blower's operation. The impeller blades catch the air and generate airflow as they rotate. Centrifugal blowers offer various impeller designs to suit different applications. The selection of the fan wheel significantly affects the blower's performance.

Caption: Centrifugal Blower Wheels

Caption: Centrifugal Blower Wheels

Impeller Housing

The housing of a centrifugal blower guides the outgoing airflow. It directs the airflow from the impeller towards the outlet. The housing construction materials, such as stainless steel, galvanized steel, or aluminum, rely on the specific application's requirements. The scroll-shaped design of the housing accelerates the airflow and helps change its direction before it exits the blower.

Caption: Aluminum, Stamped Steel, and Fabricated Steel Housings

Caption: Aluminum, Stamped Steel, and Fabricated Steel Housings

Blower Airflow

Centrifugal blowers function by creating a low-pressure area at the center of the impeller and a high-pressure area at the blade's edge, inducing the airflow. The impeller pulls air into the low-pressure area, while the centrifugal force pushes it towards the high-pressure region. This mechanism ensures constant and steady airflow through the blower.

Caption: Centrifugal Blower or Fan Design

Caption: Centrifugal Blower or Fan Design

Uses for Centrifugal Blowers

Centrifugal blowers find extensive applications across various industries due to their ability to move air efficiently. Here are some common uses for centrifugal blowers:

Clean Air Handling

Centrifugal blowers are crucial for industrial air movement, providing clean and comfortable working conditions. They are used in exhaust systems to replace exhaust air with fresh air. These blowers are suitable for clean dry gases or light particulate saturated gas.

Dust Loading

Centrifugal blowers play a vital role in dust collection systems, improving air quality and creating safe work environments. They capture, collect, and move particulate-loaded air through dust scrubbing systems. Dust loading blowers vary in configuration, from hood systems to air filtration systems.

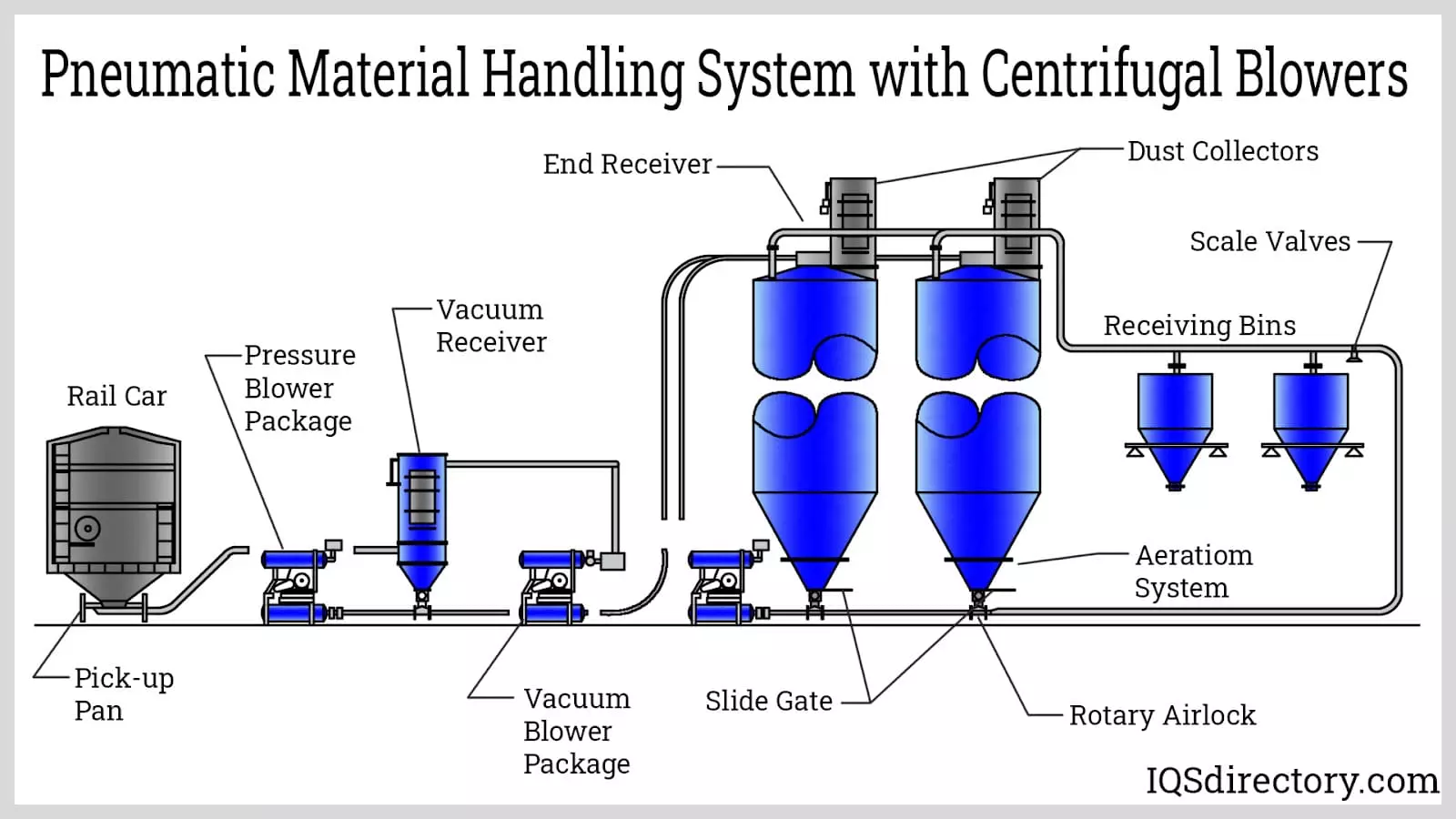

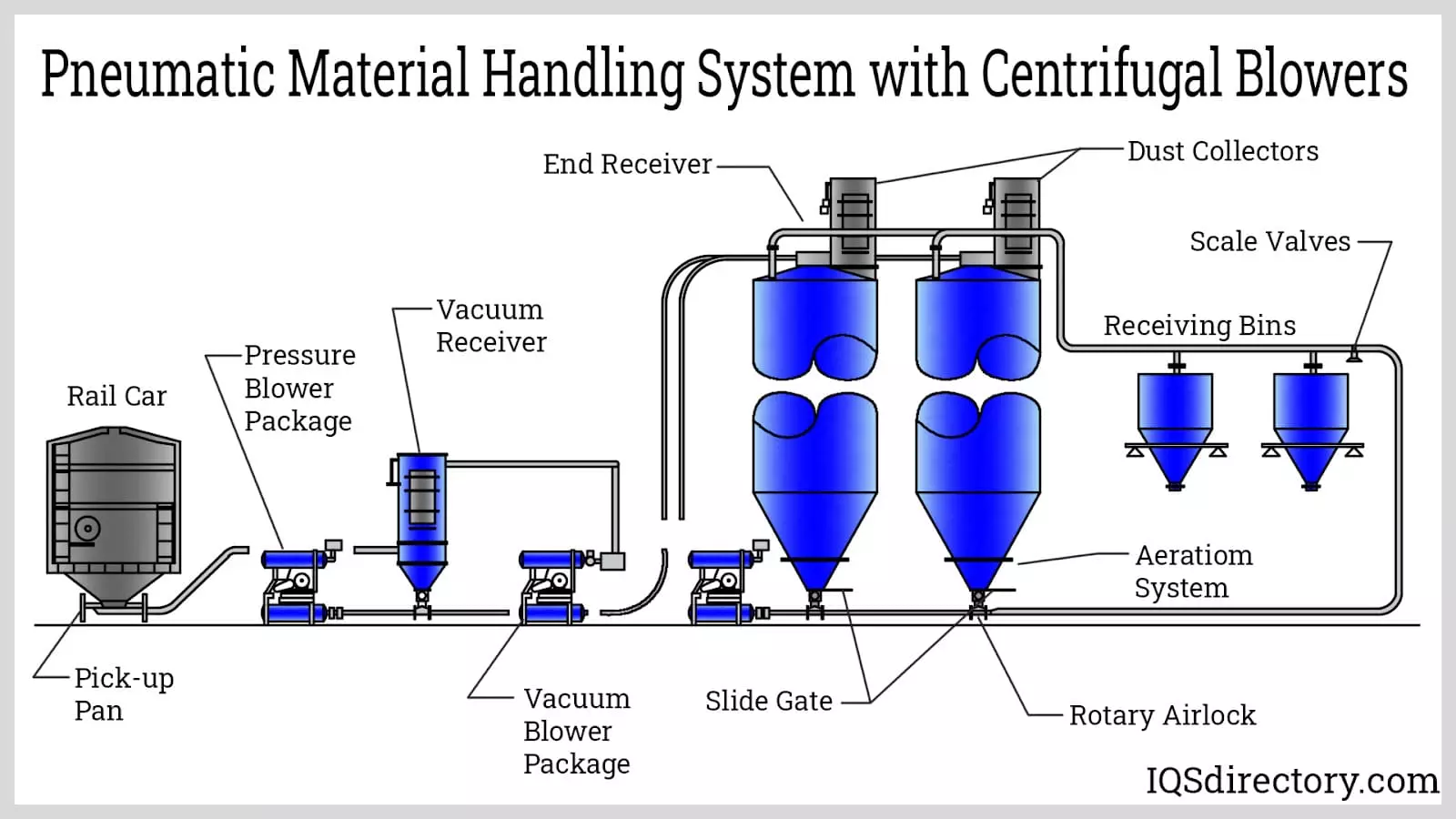

Pneumatic Material Handling

Pneumatic material handling systems rely on constant pressure to prevent fallout and clogging. Centrifugal blowers help transport various materials, such as sand, pellets, chips, and coal lumps. The blower type is determined by the material's density, requiring specific blade designs, drive mechanisms, and accessories.

Caption: Pneumatic Material Handling System with Centrifugal Blowers

Caption: Pneumatic Material Handling System with Centrifugal Blowers

Saturated Air Fan

Saturated air requires specialized centrifugal blowers designed to withstand the higher moisture content. These blowers are made of corrosion-resistant materials, such as stainless steel, and often feature protective coatings like epoxy. They are ideal for applications where air quality is a concern due to the presence of moisture.

High-Temperature Applications

Centrifugal blowers find extensive use in high-temperature applications, including heat treatments, industrial furnaces, and ovens. These blowers must be highly resilient and durable to withstand the harsh conditions. Plug blowers are commonly used for high-temperature applications, efficiently moving high volumes of air at low static pressure.

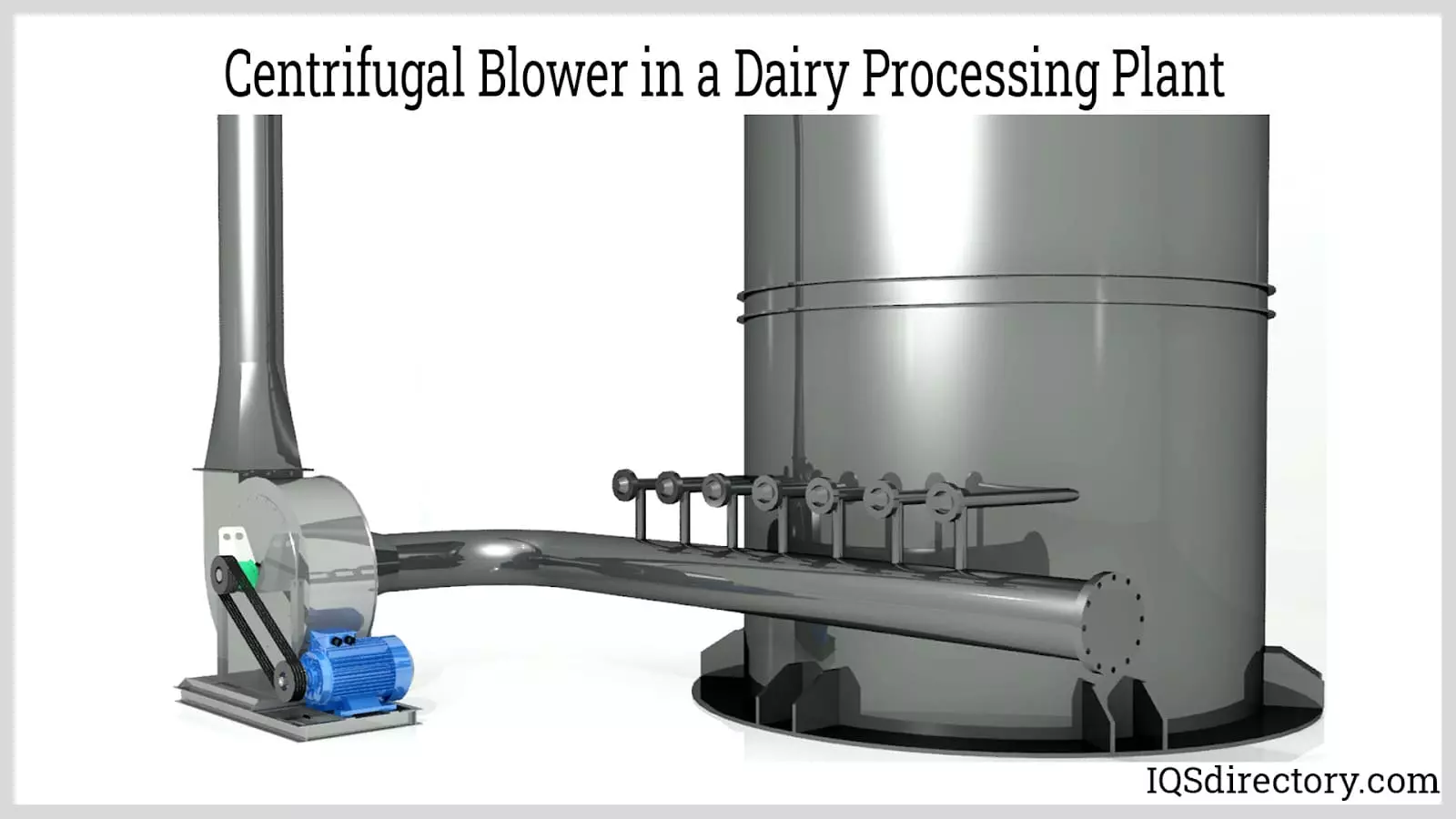

Dairy Processing

Centrifugal blowers are essential in the dairy industry for air recirculation and cleaning purposes. They must comply with Food and Drug Administration (FDA) regulations for food processing equipment. Centrifugal blowers also aid in the drying process of cheeses and dairy by-products.

Caption: Centrifugal Blower in a Dairy Processing Plant

Caption: Centrifugal Blower in a Dairy Processing Plant

Incinerator Waste Disposal

Centrifugal blowers play a critical role in incineration processes by providing the necessary air supply for combustion. They are specifically designed to meet the gas volume and pressure requirements of incinerators. The blowers used in incineration systems undergo stringent testing to comply with environmental and air quality standards.

Benefits of Centrifugal Blowers

Centrifugal blowers offer several advantages that make them a preferred choice for industrial air movement. These benefits include:

Low Maintenance

Centrifugal blowers require minimal maintenance, keeping operating costs under control. Unlike other air circulation methods, they do not accumulate dust and dirt, resulting in reduced maintenance needs. The simple modular design of these blowers further enhances their ease of maintenance and servicing.

Energy Savings

Centrifugal blowers are highly efficient, allowing for substantial energy savings. Their constant and even airflow achieves static efficiency levels of up to 84%, making them ideal for large-scale air flow systems. Energy efficiency translates to lower operating costs and improved productivity.

Versatility and Adaptability

One of the key advantages of centrifugal blowers is their versatility and adaptability to diverse industrial operations. They can be seamlessly integrated into various air flow systems and easily adjusted to meet changing requirements. Centrifugal blowers find application in industries ranging from paper mills to automobile plants, showcasing their versatility and effectiveness.

Durability and Hazard Resistance

Centrifugal blowers are designed to withstand hazardous and harsh conditions commonly found in industrial environments. They are engineered to handle corrosive substances, high temperatures, high humidity, and other challenging operating conditions. Each type of blower is meticulously crafted to meet specific manufacturing requirements, ensuring exceptional performance and longevity.

Conclusion

Centrifugal blowers are indispensable components in industrial air movement systems, offering efficient and reliable airflow. Their various types cater to diverse applications, and their low maintenance, energy efficiency, adaptability, durability, and hazard resistance make them a preferred choice for industries worldwide. Whether it's clean air handling, dust loading, material handling, or high-temperature applications, centrifugal blowers prove their worth in improving workplace safety and productivity.

![7 Best Sites for Advertising Rental Property Listings [Free + Paid]](https://saigonintela.vn/uploads/images/blog/admin/2024/02/15/7-best-sites-for-advertising-rental-property-listings-free-paid-thumb-1707966641.webp)